Get A Free Quote

1300 007 782

Call Us On:

1300 007 782G10/RMS Accredited

Competitive Rates

ZERO Accidents or Injuries

25+ years combined experience

50+ years combined experience

Competitive Rates

G10/RMS Accredited

ISO Certified

Many industries put workers at risk of potential exposure to hazardous gases: chemical processing plants, oil and gas refineries, wastewater treatment and manufacturing, to name a few. These gases need to be managed to ensure the safety of your team and avoid damaging the environment, and that’s why it’s essential to invest in gas monitoring equipment.

More than 300 workers have been injured in NSW workplaces by industrial fumes over the past three years. As a person conducting a business or undertaking, you have a responsibility to manage the risks and comply with the particular laws involving dangerous atmospheres in your workplace. Gas monitoring devices work by continuously monitoring the air around you and checking for impurities.

As Sydney-based safety experts, SSTC can help you monitor and detect dangerous gases in confined spaces and acquire the permits and documentation to comply with local laws. Here’s our guide to understanding the essential equipment and devices for gas detection and monitoring and why it’s important.

According to the World Health Organization (WHO), thousands of workers die each year due to exposure to “air pollution” (a category that includes gases, fumes and particulate matter). Many workplaces contain compressed gas cylinders, which contain gas stored under significant pressure. Potential hazards involve damage to a regular or valve, a heat source causing a rupture or an uncontrolled release of gas. Potential dangers to workers include:

Inert gases like helium plus non-flammables like carbon dioxide and nitrogen can create a suffocation hazard, especially if improperly stored.

When toxic gases are inhaled, they’re quickly absorbed by the bloodstream and can quickly impact organs like the lungs, kidneys or liver. The damage they cause varies in severity depending on factors like length of exposure to the toxin and how quickly first aid is delivered.

Flammable gases are frequently used on worksites, especially as fuel sources. Common culprits like LPG, hydrogen, propane and methane can cause fires and explosions when even the smallest gas leaks are left unchecked. When leaked into a confined space that doesn’t have enough ventilation, dangerous gas will stay within its explosive range and remain volatile.

Even if it doesn’t cause immediate danger, being exposed to harmful gases at work can lead to long-term lung damage and conditions like lung cancer and hard metal pneumoconiosis.

Like other forms of technology, gas monitoring devices have evolved over the years as new developments change the landscape. The main components that make up a gas detection system now include:

Gas sensors detect the presence and concentration of gases, and there are different varieties designed for the differing gas types and applications. Electrochemical sensors, for example, produce a current when the gas reacts with an electrode. Catalytic bead sensors use a heated bead that reacts to combustible gases.

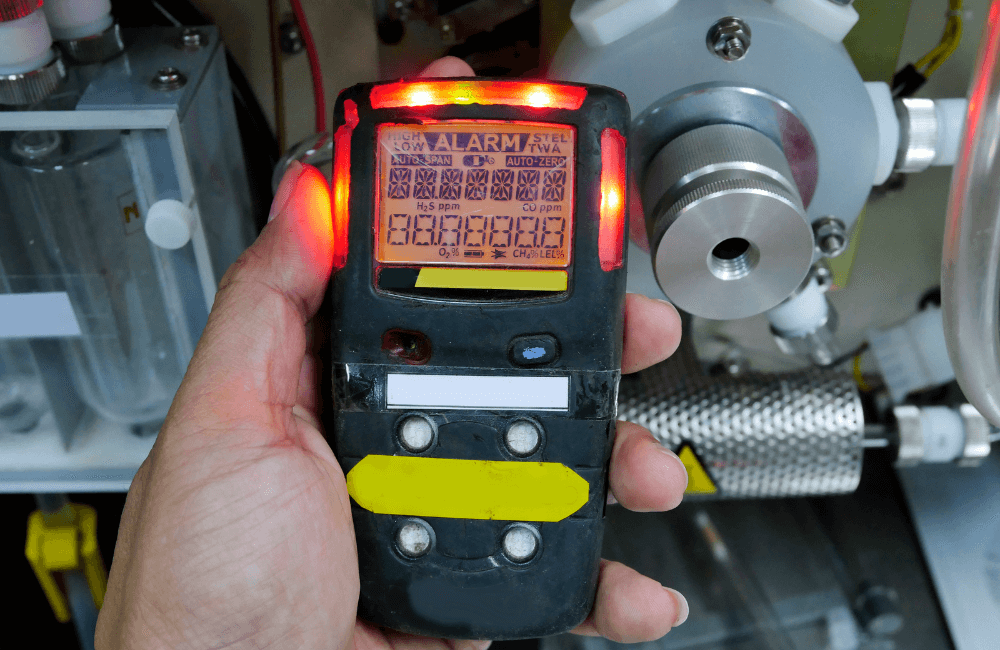

Gas detectors are devices that constantly check for the presence of gas in the air. They can be fixed or portable and are typically made up of components like a sensor, alarm system and power source.

A gas detector’s alarm system sends out an alert when it detects that gas levels have climbed dangerously high and immediate action needs to be taken.

The central monitoring unit gathers the data from every connected sensor and displays it to the safety operator, often on a dashboard in real-time.

Many environments, like underground mines and industrial plants, require gas detection systems with multiple monitoring and alarm components. It’s essential for these devices to be responsive, reliable, and user-friendly in the dangerous environments in which they’re most commonly used.

It’s important to choose a gas detector that will provide accurate data under differing environmental conditions. But there are some variables to choosing gas monitoring equipment depending on your industry and its application. Some of the key factors to consider when selecting gas monitoring devices include:

Depending on your workplace, there is a wide range of gases you may be exposed to, including carbon monoxide, carbon dioxide, LPG, hydrogen, propane, ammonia, hydrogen chloride, etc. Some gases are harmful at different concentration ranges than others, and quality gas detection equipment needs to pick up gas at its necessary concentration levels. Some gas monitoring devices pick up multiple types of gas.

A good gas detection system needs an accurate sensor that can offer precise readings and avoid false positives or negatives. This often includes picking up gas at the lower explosive limit or the permissible explosive limit, depending on the gas you’re working with.

In a confined space or another area where a gas leak can cause immediate danger, it’s important for a device to have a fast response time. Once it detects dangerous gas, your device needs to trigger the alarm fast enough for the rescue team to spring into action.

Gas monitoring and detection equipment requires routine maintenance like cleaning, sensor checks and battery replacement. Sensors have finite lifespans, and your detection advice needs to be sturdy enough to survive the working conditions. Regular inspections and maintenance are a matter of life and death, so it’s important to know how much checking and maintenance is required before you commit to your purchase.

If ensuring safety in your workplace while working with gas feels overwhelming with the amount of logistics and regulations to consider, SSTC can make the journey easier for you.

For the highest levels of protection and guaranteed legal compliance, SSTC can help you. A company with competitive rates and over 25 years of combined experience, we’re trusted by businesses nationwide, including some of Australia’s largest construction companies.

SSTC’s gas detection & monitoring services cover all your bases, ensuring a safe workspace when using gas. We can supply all the equipment you need for entering and exiting a confined space with the threat of gas danger, including gas monitoring devices, tripods, full arrests, breathing apparatuses, radio communication devices and any other safety measures you may require. Our gas detection and monitoring equipment includes four gas and five gas monitors, with our five gas monitors about to detect over 100 VOC gases.

SSTC’s confined space standby officers are trained in first aid and skilled in preparing a confined space for opening and freeing gas. We offer a confined space safety officer to monitor your worksite, observing the risks and rescuing your worker if necessary.

Finally, working with gas involves acquiring the right training, permits and documentation. Our consultations can help you with all necessary documentation, including risk assessments, safe work method statements and rescue plans. SSTC is a highly certified team in gas detection and confined space management and has full accreditation, so safety is always put first.

For the highest-quality gas monitoring equipment, documentation and personnel, contact the SSTC team for a free quote.